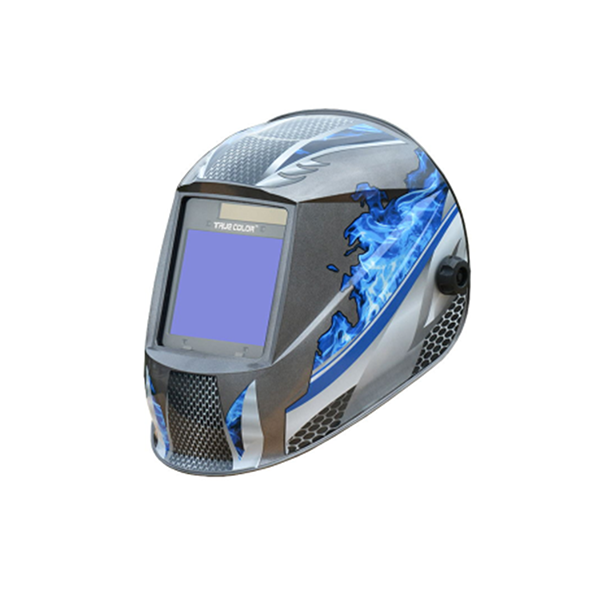

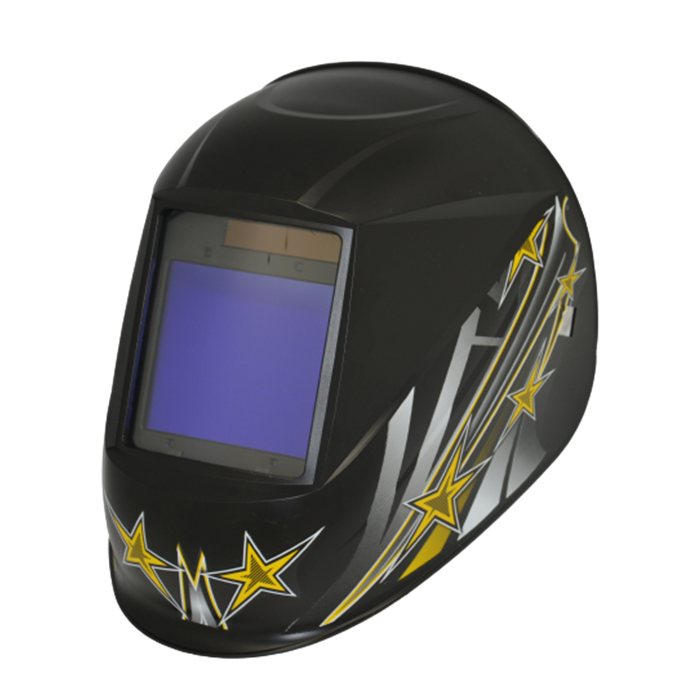

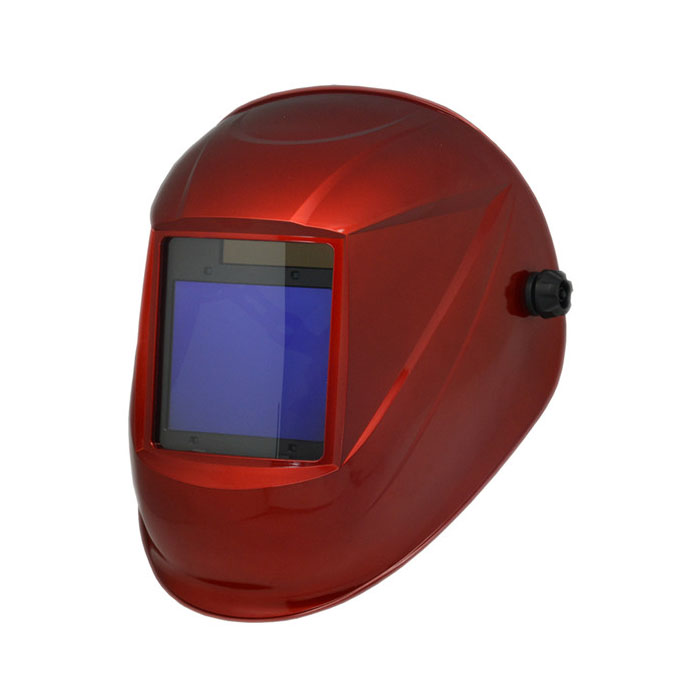

Ifasitela elikhulu Solar Automatic Photowelding Helmet

Incazelo

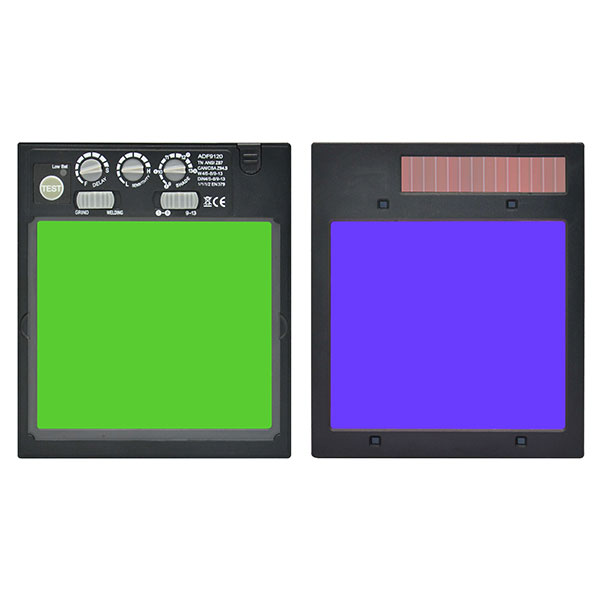

Isigqoko se-Auto Darkening siklanyelwe ukuvikela amehlo akho nobuso ezinhlansini, ku-spatter, nemisebe eyingozi ngaphansi kwezimo zokushisela ezivamile. Isihlungi Sokwenza Ubumnyama Ngokuzenzakalelayo sishintsha ngokuzenzakalelayo sisuka esimweni esicacile siye esimweni esimnyama lapho i-arc ishaywa, futhi sibuyela esimweni esicacile lapho ukushisela kuma.

Izici

♦ Isigqoko sokuzivikela sochwepheshe

♦ Isigaba sokubuka : 1/1/1/1 noma 1/1/1/2

♦ Umbono omkhulu kakhulu

♦ Ukushisela nokugaya nokusika

♦ Ngamazinga we-CE, ANSI,CSA,AS/NZS

Imininingwane yemikhiqizo

| IMODE | I-TN360-ADF9120 |

| Isigaba se-Optical | 1/1/1/1 noma 1/1/1/2 |

| Ubukhulu besihlungi | 114×133×10mm |

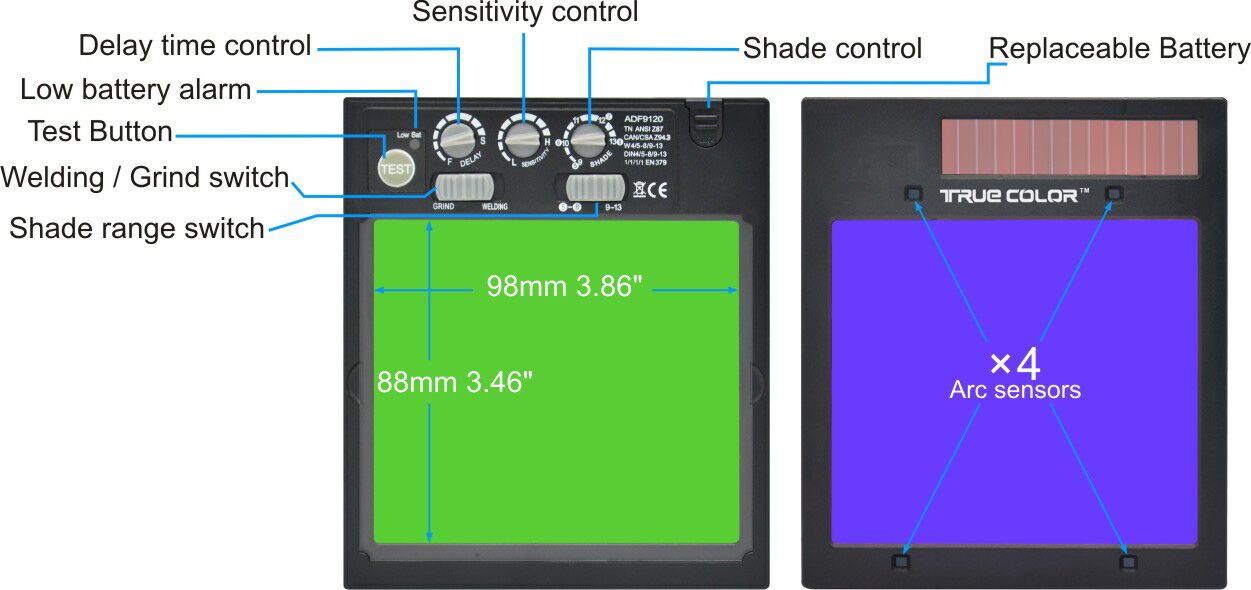

| Buka usayizi | 98x88mm |

| Umthunzi wesimo esikhanyayo | #3 |

| Umthunzi wesimo esimnyama | Umthunzi Oguquguqukayo DIN5-8/9-13, Ukulungiselelwa Kweknobhu Yangaphakathi |

| Ukushintsha isikhathi | 1/25000S ukusuka ekukhanyeni kuye ebumnyameni |

| Isikhathi sokuthola ngokuzenzakalelayo | 0.2 S-1.0S Fast to Slow, Ukulungiswa okungenasinyathelo |

| Ukulawula ukuzwela | Okuphansi kuya phezulu, ukulungiswa okungenasinyathelo |

| Inzwa ye-arc | 4 |

| I-TIG Amps Ephansi Ilinganiselwe | AC/DC TIG, > 5 amps |

| Umsebenzi wokugaya | Yebo (#3) |

| Ibanga lomthunzi wokusika | Yebo (DIN5-8) |

| I-ADF Zihlole | Yebo |

| Ibhethi ephansi | Yebo (i-LED ebomvu) |

| Ukuvikelwa kwe-UV/IR | Kufika ku-DIN16 ngaso sonke isikhathi |

| Ukunikezwa kwamandla | Amaseli eSolar nebhethri ye-Lithium Eshintshekayo ( CR2450) |

| Vula/vala | Okuzenzakalelayo okugcwele |

| Okubalulekile | Ileveli yomthelela ephezulu, Inayiloni |

| Izinga lokushisa elisebenzayo | kusuka -10℃–+55℃ |

| Ukugcina izinga lokushisa | kusuka -20 ℃–+70 ℃ |

| Iwaranti | iminyaka engu-2 |

| Okujwayelekile | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Ibanga lohlelo lokusebenza | I-Stick Welding (SMAW); I-TIG DC∾ I-TIG Pulse DC; I-TIG Pulse AC; I-MIG/MAG/CO2; I-MIG/MAG Pulse; I-Plasma Arc Cutting (PAC); I-Plasma Arc Welding (PAW); Ukugaya. |

1. Ngaphambi Kokushisela

1.1 Qinisekisa ukuthi amafilimu okuvikela angaphakathi nangaphandle ayakhishwa kumalensi.

1.2 Hlola ukuthi amabhethri anamandla anele okusebenzisa umakalabha. I-cartridge yesihlungi ingahlala amahora okusebenza angu-5,000 inikwa amandla amabhethri e-lithium namaseli elanga. Uma amandla ebhethri ephansi, isibonisi se-LED Yebhethri Ephansi sizokhanya. Ilensi ye-cartridge yesihlungi ingase ingasebenzi kahle. Shintsha amabhethri (bheka Ukushintshwa Kwebhethri Lokulungisa).

1.3 Hlola ukuthi izinzwa ze-arc zihlanzekile futhi azivinjwanga uthuli noma imfucumfucu.

1.4 Hlola ukuthi ibhande lekhanda liyaqina yini ngaphambi kokusetshenziswa ngakunye.

1.5 Hlola zonke izingxenye zokusebenza ngaphambi kokuzisebenzisa ukuze uthole izimpawu zokuguga noma zokulimala. Noma yiziphi izingxenye eziklwetshiwe, eziqhekekile, noma ezinemigodi kufanele zishintshwe ngokushesha ngaphambi kokuba zisetshenziswe futhi ukugwema ukulimala okukhulu komuntu siqu.

1.6 Khetha inombolo yomthunzi oyidingayo ekujikeni kwefindo lomthunzi (Ukubona Ithebula Lomhlahlandlela Womthunzi). Okokugcina, qiniseka ukuthi inombolo yomthunzi iyisilungiselelo esilungile sohlelo lwakho lokusebenza.

Qaphela:

☆SMAW-Shielded Metal Arc Welding.

☆TIG GTAW-Gas Tungsten Arc (GTAW)(TIG).

☆MIG(Heavy)-MIG ezinsimbini ezisindayo.

☆SAM Shielded Semi-Automatic Arc Welding.

☆MIG(Light)-MIG on light alloys.

☆PAC-Plasma Arc Cutting

1. Ukuhlanza nokubulala amagciwane: Hlanza izindawo zokuhlunga njalo; ungasebenzisi izixazululo eziqinile zokuhlanza. Hlala njalo ugcine izinzwa namaseli elanga ehlanzekile usebenzisa izicubu/indwangu ehlanzekile engenalambu. Ungasebenzisa utshwala nokotini ukuze usule.

2. Sebenzisa okokuhlanza okungathathi hlangothi ukuhlanza igobolondo lokushisela kanye nebhande lekhanda.

3. Shintsha amapuleti okuvikela angaphandle nangaphakathi ngezikhathi ezithile.

4. Ungacwilisi ilensi emanzini noma kunoma yiluphi olunye uketshezi. Ungalokothi usebenzise ama-abrasives, ama-solvents noma izihlanzi ezisekelwe kuwoyela.

5. Ungasikhiphi isihlungi esizenza mnyama ku-helmet. Ungalokothi uzame ukuvula isihlungi.